Origami boats are sometimes referred to as “frameless”. This has led to some confusion. Technically, Origami boats use “frameless construction” but they are framed. The difference is this: Framed construction uses frames to bend and hold the plates to shape. Frameless construction (origami method) relies on conical projection to bend and hold the plates to shape.

For strength, frames (stringers) are added to the origami plates before they are bent to shape, and sized according to standard metal scantlings. Angle or T bars are preferred for strength and because they provide a convenient attachment for interiors. Bulkheads, girders, and posts are added after the boat has been brought to shape to add strength where required. Where possible these are welded to the stringers, not the hull, to minimize cosmetic distortion to the hull plate. This is especially true for alloy boats that are intended to remain unpainted. Welding to a curved plate should only be done at the edges.

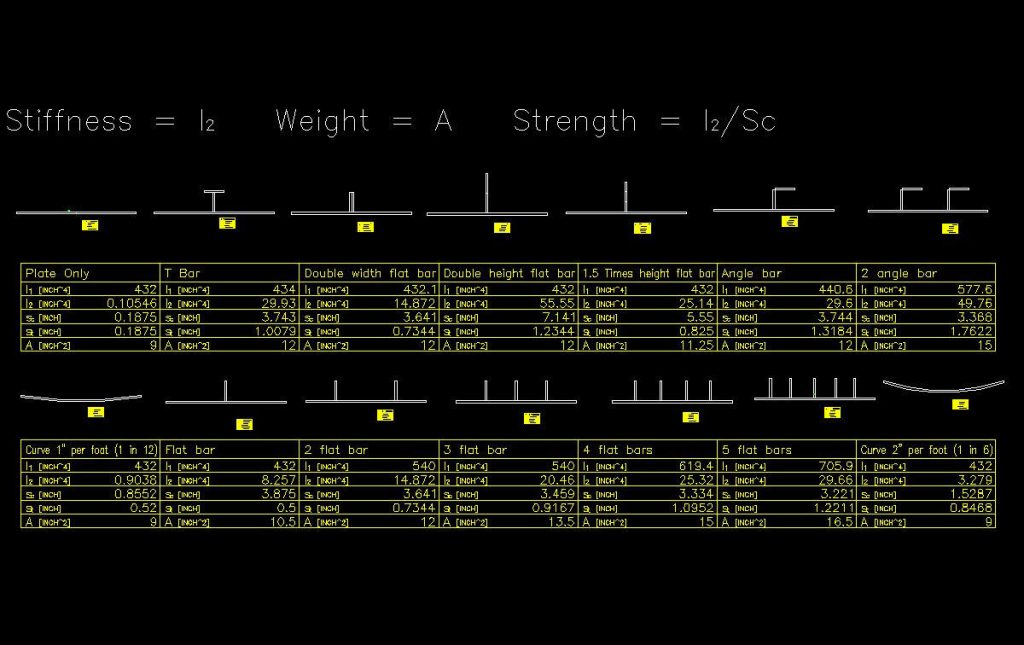

The following study shows the effects of various framing styles on the resulting strength and stiffness of the plating. It can be seen from this study that increasing the height of the frames provides the best result but uses up the interior space. Hull curvature provides a modest increase in strength, increasing with the amount of curvature.

Summary:

| Method | stiffness / weight | strength / weight |

| Plate Only | 0.0 | 0.1 |

| Flat bar | 0.8 | 0.2 |

| T Bar | 2.5 | 0.7 |

| Angle bar | 2.5 | 0.7 |

| 2 angle bars | 3.3 | 1.0 |

| 2 flat bars | 1.2 | 0.3 |

| 3 flat bars | 1.5 | 0.4 |

| 4 flat bars | 1.7 | 0.5 |

| 5 flat bars | 1.8 | 0.6 |

| Double width flat bar | 1.2 | 0.3 |

| Double height flat bar | 4.6 | 0.7 |

| 1.5 Times height flat bar | 2.2 | 0.4 |

| Curve 1 part in 12 | 0.1 | 0.1 |

| Curve 1 part in 6 | 0.4 | 0.2 |

Details