A Tale of 2 Origami Boats

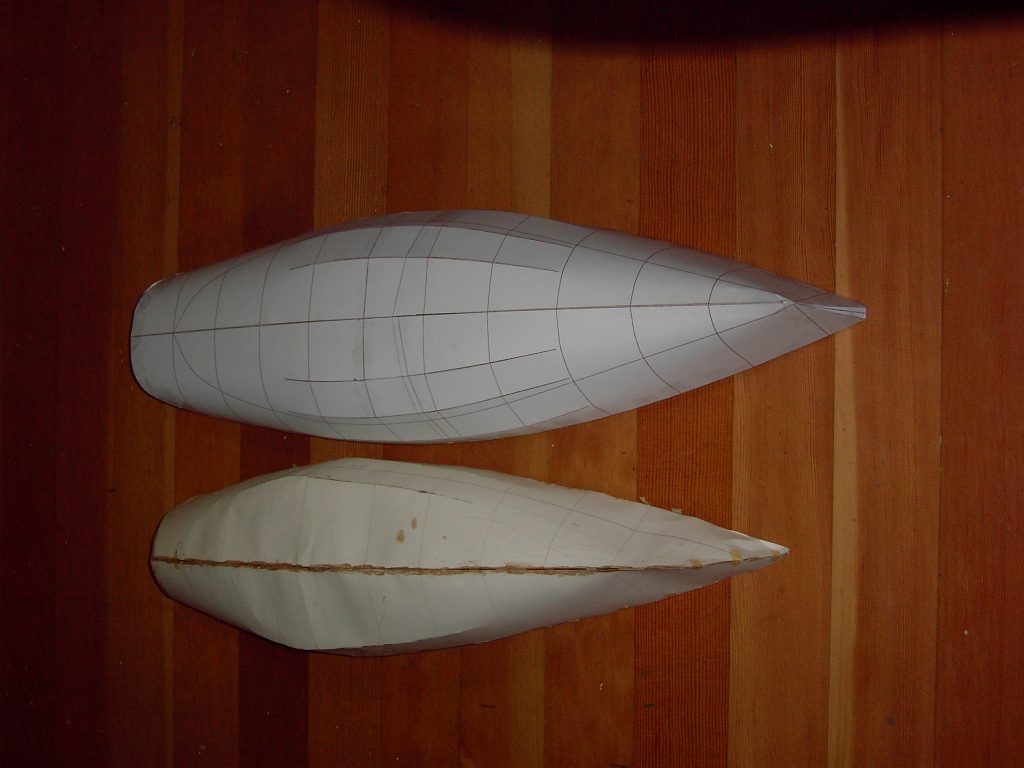

Origami or Frameless construction has come a long ways since the introduction of computer aided design. The two side by side models shown above represent traditional vs modern origami shapes.

The traditional shape was created using conventional methods. A pattern is “guessed” from experience and existing patterns, then a model is assembled, and the pattern is then adjusted to improve the shape. This process is repeated over and over until the pattern approximately delivers the shape desired. The slightly smaller hull in the above models reflect dozens and dozens of trials to get a fair shape.

As can be seen, the traditional method leaves much to be desired. The problem is that in small scale, the model looked great. It was not until the pattern was transferred to a larger scale that the problems became apparent. While the hull shown will “fold”, there will be a lot of “final adjustment” and the result will be rather crude with narrow ends with a “V” profile. Not at all the profile of a modern yacht.

The slightly larger model is the G55 computer assisted pattern. This was drawn using a very different technique. Rather than starting with the pattern, we start by drawing a 3D model of the yacht we want to build on the computer. As with all designs, this model itself was inspired by a successful offshore design, with proven performance. We ran this model through computerized performance prediction software and tweaked the shape until the models performed as desired. The computer then “unfolds” the 3D model yacht into a 2D pattern using millions of calculations.

Thus, when we fold an origami pattern we know with confidence what the final hull will look like. We also know with confidence how the yacht will perform. The expected speed, displacement, stability, etc.

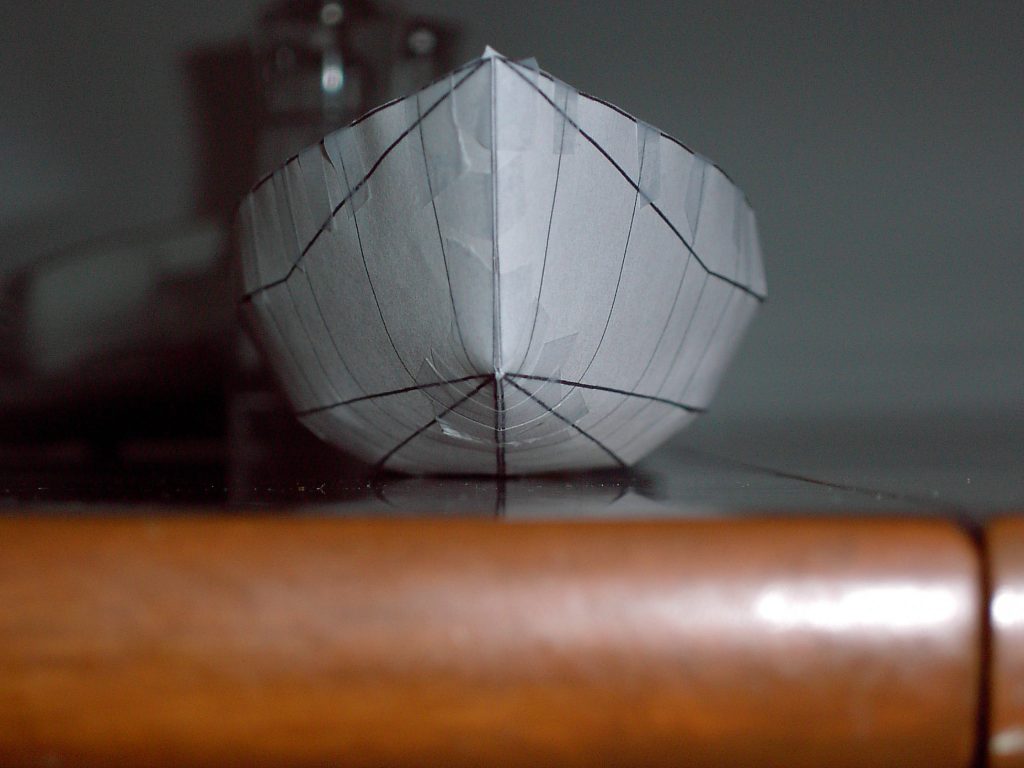

The photo on the left shows the predicted U shaped profile for the G55 bow. Notice the “U” shapes of the station lines. Not at all what is seen in traditional origami.

Now look at the photo on the right. This was a chance photo taken from inside the bow of the G55 during construction. Notice the chains lying down the sides and the “U” shape formed. More interestingly, look at the concentric circles radiating outward from the cutwater. This was a chance reflection given off by the flash. It is somewhat like the conical shape of the bulbous bow found on large ships.

The G55 doesn’t have a bulbous bow. Rather, the photo shows similar sections. It helps explain why the modern U shaped hull outperforms the V profile of old, contrary to what common sense might indicate. The U shape helps move the underwater profile forward, bringing buoyancy into the bow. This helps reduce hobby horsing, increase effective waterline, while reducing wave making and drag.

Similarly, look at the stern section. Rather than the V profile of traditional origami stern sections, modern origami origami achieves a U profile stern with high buoyancy and a flat run-off to allow for down-wind surfing in large seas. The V shaped stern in contrast will tend to “squat” when running off in large seas, increasing the risk of being “pooped”.

The risk of being pooped is especially critical for offshore boats. As conditions worsen there comes a point where for survival reasons the boat must run-off to reduces forces. As the waves build you do not want to find yourself on the crest of a breaking wave, with the very real risk of broach or capsize.

It is critical that the boat be able to surf ahead of the break. Otherwise, if the yacht tends to squat by the stern as speed increases, the breaking sea behind will sweep the yacht from stern to stem. The cockpit will be flooded and there is a very high risk of damage. Anything not tied down on deck will be swept overboard, including the crew. Depending on companionway design, water from the cockpit may well flood below into the cabin. At this point the yacht and crew are in true danger, if not already lost.